Balancing

Balancing is the process of aligning the main inertia axis with the geometrical axis of rotation by adding or removing the rotating solid material. This decreases the influence of acting centrifugal forces, which results in an increase in quality and reliability of the rotating device. Through balancing we primarily want to achieve the least possible mechanical stress of the rotor and a decrease in load of bearings, the lifetime of which mainly depends on speed of rotation and load. The maximum bearing lifetime can be achieved, if a component of the centrifugal force from the total static load is less than 10%. Furthermore, balancing decreases vibrations that cause the machine parts to get loose and they are a noise source. In isolated cases, they can even cause a damage to health. An accompanying effect of balancing is the possibility of increasing the operating speed, thus increasing the device output. Distribution of the solid mass is determined according to positions of the centre of gravity and the main central inertia axis. Imbalance occurs, when the rotation axis differs from the main central inertia axis.

Dynamic imbalance

It is the most common case of imbalance. Its condition is that the main central inertia axis.is not parallel nor crosses the rotation axis. Thus, the main central inertia axis is non-parallel with the rotation axis. To completely eliminate the dynamic imbalance, the correction in two balancing planes should be carried out.

Static imbalance

The condition of the static imbalance is that the solid centre of gravity is not on the axis of rotation, but this should be parallel with the main central inertia axis. Correction of the static imbalance can be carried out by increasing the mass. In the best case, correction is carried out in a plane of the centre of gravity where an increase of the mass ensures a centre-of-gravity shift to the axis of rotation.

We offer balancing:

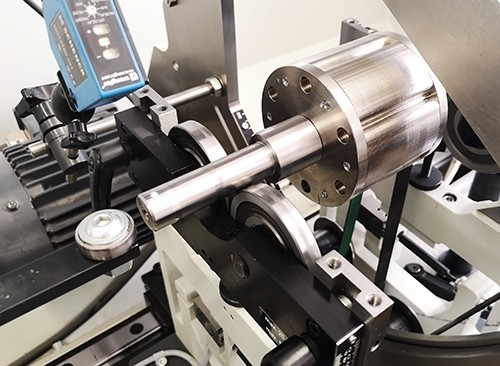

On our SCHENCK balancing machine, we perform static and dynamic balancing of solids of revolution that comply with the following parameters:

- mass - min. 0.5 kg / max. 50 kg

- solid diameter - max. 600 mm

- solid length - min. 90 mm / max. 970 mm

- shaft diameter - min. 9 mm / max. 63 mm

If you are interested in balancing, please contact our specialist.